To mark the opening of this year’s Hannover Messe Industrie (Hanover Industry Trade Fair) the digital sector association Bitkom has presented the outcomes of a new study on the topic of “Industry 4.0”.

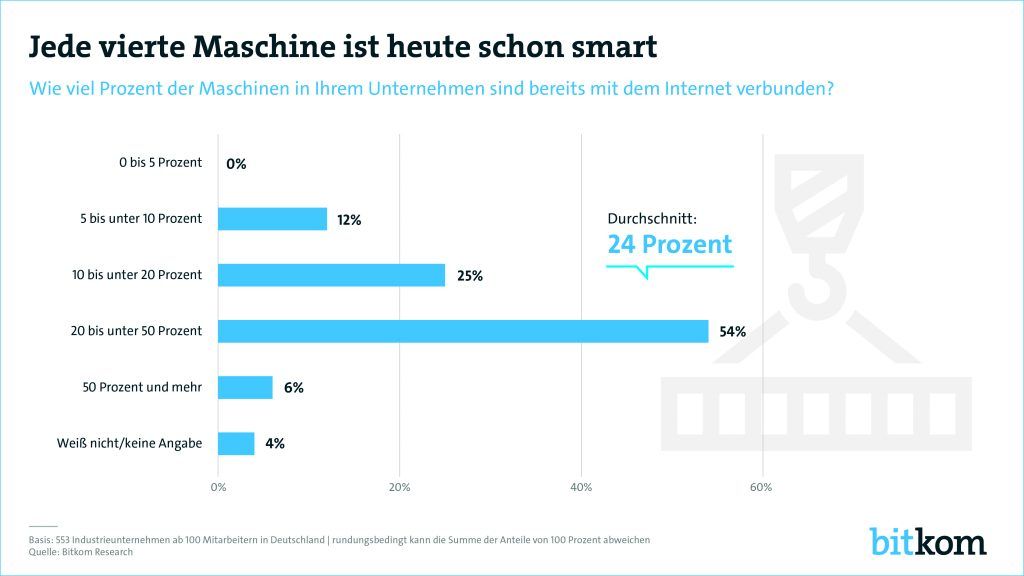

According to the header of the attendant press release, 24 percent of the machines and facilities at German companies are already “smart”. On closer inspection, however, this means little more than “connected with the internet”. Nevertheless: “Machine-to-machine communication has meanwhile become the reality in factories,” according to Bitkom president Achim Berg.

The industrial companies surveyed in the Bitkom study identify the required allocation of resources as representing the biggest hurdle to deploying Industry 4.0. Accordingly, 72 percent of the participants reported that high investment outlay is impeding the deployment of Industry 4.0 at their companies. Other hurdles are data protection (58 percent) and data security (56 percent) as well as a shortage of suitably qualified employees.

Yet it is actually not necessary to make costly investments in the “industrial internet”: with Retarus’ Enterprise Messaging Services you only pay “per use”. Investment in hardware and software licenses is reduced to zero. Retarus’ Cloud Services offer businesses a flexible communication layer for their IoT offerings – without compromising on delivery quality or affecting existing business applications.

Then there is nothing standing in the way of reaping the benefits of digitalization any longer – according to the Bitkom survey, users and planners hope that the deployment of Industry 4.0 solutions will lead to improved processes (68 percent) and higher capacity utilization rates (58 percent), followed by lower production costs (43 percent) as well as quicker implementation of individualized customer requests (41 percent).